Understanding offset with your vinyl cutter if you ve been cutting vinyl and have had a difficult time achieving accurate corners it could be the offset setting.

Vinyl express what is blade offset.

Blade offset calibration the vinyl spooler comes with a blade offset calibration tool that cuts a physical test from the target vinyl cutter or plotter which is used to establish which offset amount value best suits the cutter or plotter in question.

The blade offset value is used in calculating the distance the blade must travel past a corner in order for the tip of the blade to reach the same point when its direction changes.

Set blade depth blade depth is how far the blade sticks out of the end of the blade holder and is a major factor in how well the machine cuts and how easy or difficult it will be to weed the material.

The blade offset value can be changed in the cutter settings window which can be accessed by choosing cutter settings from the cutter menu or clicking the settings button in the cut window.

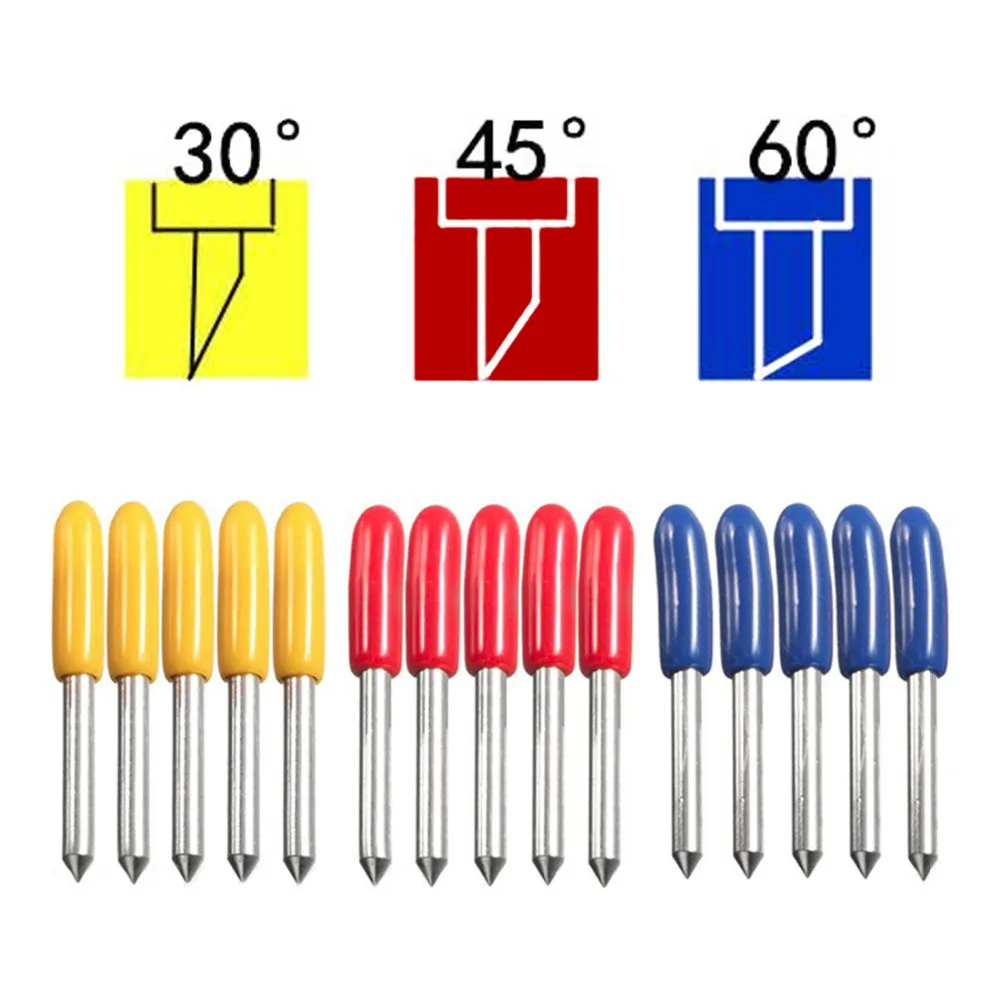

In the most basic of definitions blade offset is the distance from the tip of the blade to the center of its shaft.

Fig 1 shows the edge lifting of this graphic with the standard 45 blade.

If you have tried to cut a thicker material like flock vinyl or twill on your cutter by changing to a higher degree blade but failed to adjust the offset chances are you failed or.

This was cut on a vinyl express qe6000 which has a high quality digital servo motor and cuts fine detail with amazing precision.

It s an elegant serif font cut at 1 2.

Maximize your r series vinyl cutter s performance by making the following adjustments to your cutter s and software s default settings.